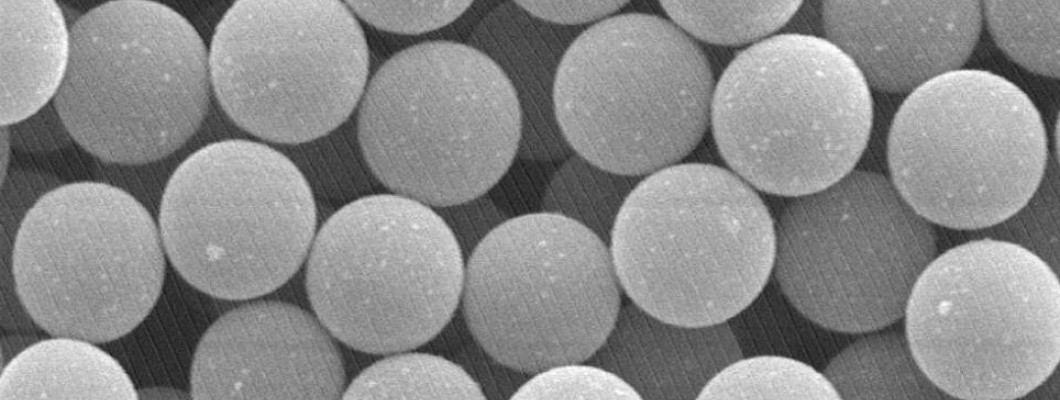

The size of these particles lies between 0.1 to

100 μm.

Microparticles are considered to have an increased surface-to-volume ratio than

at a macroscale, therefore,

depict a different behavior. The larger microparticles can

be viewed without any assistance; however, the smaller particles require

magnification to be seen.

Even with the visibility of the particles, the

structure of the particle is too small for a human eye to see. The industrial

microparticle is a magnetic core that is

surrounded by the second material.

These particles are mixed with other substances which are used for specified

applications. The applications vary as it

depends on the properties of the

outer shell. They can be used anywhere from separating valuable metals from

rock, leading to the purification of water.

As stated above, microparticles

have a larger surface area in comparison to various other materials, which

causes certain particles to have different reactive

behavior on small scales in

comparison to large scales. The most common reactions originate from certain

metals. Upon exposure to these metals to wear

and friction, they can become

highly volatile and even explosive in certain cases. The use of microparticles

is very diverse as it is being used as conductive

coatings, manufacturing

of glass, formation of lubricants, nuclear reactors, metallic alloys, and

structural materials. It is also used as metal composites for bearings

and

liners engines. Microparticles are also used as support materials for the

composition of precision metal powder catalysts which are used to increase the

conductivity.

It is also used to create a metal matrix for reducing friction.

Microparticles are also used as a chromatography medium. Because of its

applications, it is also used as

an adsorbent in the defluorination of drinking

water. They are also used as air filters in vehicles while enhancing the

efficacy of filters by absorbing and decomposing

carbon monoxide leading to a

decrease in environmental pollution.

Leave a Comment