In the world of materials science, MAX phase powders represent a groundbreaking class of materials that combine the best properties of ceramics and metals. These unique materials have gained significant attention due to their exceptional mechanical, thermal, and chemical properties.

This blog explores the types, applications, and advantages of MAX phase powders, shedding light on why they are considered a cornerstone of advanced materials.

What Are MAX Phase Powders?

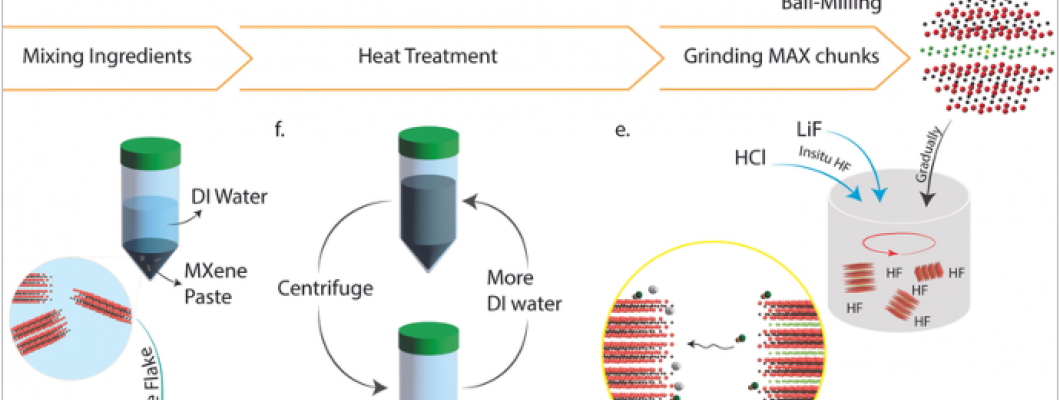

MAX phases are a family of layered ternary carbides or nitrides with the general formula Mn+1AXn, where:

M: A transition metal (e.g., titanium, vanadium, or chromium).

A: An A-group element (e.g., aluminum or silicon).

X: Carbon or nitrogen.

n: An integer ranging from 1 to 3, representing the number of atomic layers in the structure.

These materials are unique because they exhibit a combination of metallic and ceramic properties, making them highly versatile for a variety of applications.

Types of MAX Phase Powders

MAX phase powders are classified based on their composition and the "n" value in their formula. The main types include:

211 Phases (n=1):

Example: Ti2AlC, Cr2AlC.

Known for their excellent thermal stability and oxidation resistance.

312 Phases (n=2):

Example: Ti3SiC2, Ti3AlC2.

Provide a balance of mechanical strength and electrical conductivity.

413 Phases (n=3):

Example: Ti4AlN3.

Exhibit superior toughness and damage tolerance.

Each type has specific properties that make it suitable for targeted applications, ranging from structural components to electronic devices.

Applications of MAX Phase Powders

MAX phase powders find applications across diverse industries due to their unique combination of properties. Key applications include:

1. Aerospace and Defense

High-Temperature Components: MAX phases are used in jet engines and thermal barriers for their ability to withstand extreme conditions.

Protective Coatings: Their resistance to oxidation and corrosion makes them ideal for protecting surfaces in harsh environments.

2. Electronics

Conductive Ceramics: MAX phases provide electrical conductivity while maintaining ceramic-like durability.

Thermal Management: Their excellent thermal conductivity is leveraged in heat sinks and electronic packaging.

3. Energy Sector

Fuel Cells: MAX phases are used in solid oxide fuel cells for their chemical stability and electrical conductivity.

Nuclear Reactors: Their radiation resistance makes them ideal for components in nuclear environments.

4. Medical Technology

Biomedical Implants: Their biocompatibility and wear resistance make them suitable for orthopedic and dental implants.

5. Manufacturing

Tooling: MAX phases are used in cutting tools and molds due to their high wear resistance and toughness.

Advantages of MAX Phase Powders

The unique properties of MAX phase powders provide several advantages, including:

High Thermal Stability:

Can withstand extreme temperatures without degradation.

Oxidation and Corrosion Resistance:

Offer exceptional durability in chemically aggressive environments.

Electrical and Thermal Conductivity:

Combine metallic conductivity with ceramic-like insulation properties.

Damage Tolerance:

Exhibit self-healing behavior, improving long-term reliability.

Lightweight and Strong:

Provide high strength-to-weight ratios, crucial for aerospace and automotive applications.

Eco-Friendly:

Many MAX phases are non-toxic and recyclable, aligning with sustainability goals.